Radial Oil Seals with sealing lip made of elastomer types

NBR, FPM (FKM), ACM, AEM, EPDM, HNBR, VMQ (MVQ)

ALL TYPES ALSO AVAILABLE WITH STAINLESS STEEL STIFFENING RING AND STAINLESS STEEL SPRING. Other types not listed also available.

Type | Profil | Description | Application: | Standard / Description |

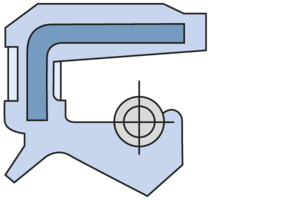

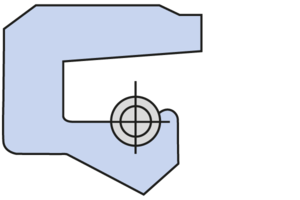

A |  | Rubberized stiffening ring | Good static sealing behavior even with low viscosity media and split housings, as well as for housings with increased thermal expansion. | Type according to DIN 3760 |

AS |  | Rubberized stiffening ring with protective lip | See type A, as well as for protection of the sealing lip against foreign liquids, dust and dirt from outside. | Type according to DIN 3760 |

AW |  | Rubberized grooved stiffening ring | Good static sealing behavior even with low-viscosity media and split housings, as well as with housings with increased thermal expansion. The grooving serves to facilitate assembly and prevents skewing and springback.

| W=Waved |

| Type | Profil | Description | Application: | Standard / Description |

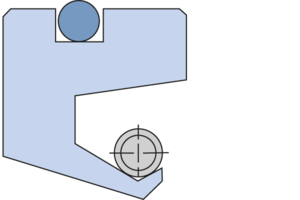

A-TR1 |  | For large dimensions | In heavy industry, gear manufacturing, aluminum and steel industry, rolling mills, paper industry, wind turbines, etc. | TR= Textile + Rubber The holding part is made of rubber fabric on the outer diameter. Slotted version also possible

|

AS-TR1 |  | For large dimensions with vertical groove | See A-TR1. To protect the sealing lip against foreign liquids, dust and dirt from outside. | |

A-TR2 |  | For large dimensions with protective lip | See A-TR1 with vertical groove at the back for additional lubricant supply, for back-to-back installation. | |

AS-TR2 |  | For large dimensions with vertical and horizontal groove | See A-TR1 with vertical and horizontal groove at the back for additional lubricant supply, for back-to-back installation. |

Rotary shaft seals Housing with PTFE sealing lip

Housing made of steel, aluminum, Eder steel 1.4301 and 1.4401

Sealing lip made of PTFE with the following fillings:

unfilled, with glass fiber, with glass + graphite, with glass + molybdenum sulfide (MoS²), with graphite, with carbon fiber, with bronze, with polyimide, with MPPS-FDA approval, with Ekonol

Type | Profil | Description | Application | Standard / Description: |

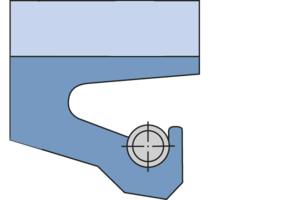

PSO 10 |  | PTFE sealing lip clamped without rubber | Used in gearboxes, agitators, vacuum pumps, pumps for chemical applications, compressors, etc. | Low friction, long life, good chemical resistance (depending on design), Prerequisite for the function: Shaft: Hardness: 45 to 60 HRC |

PS 10 |  | PTFE sealing lip clamped with rubber | ||

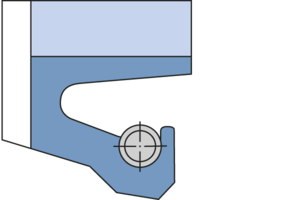

PS 11 |  | PTFE sealing lip with rubber clamped | ||

Other types are also available |

Radialwellendichtringe aus PTFE ungefüllt

Type | Profil | Description | Application | Standard / Description |

APTFE-1 |  | Solid PTFE with and without spring. Also available with dust lip | For aggressive media and in the food sector | Low friction, long service life, good chemical resistance |

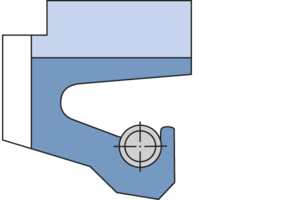

APTFE-2 |  | Solid PTFE with O-ring | For aggressive media and in the food s | Low friction, long life, good chemical resistance, better preload due to O-ring |