Rod seals for hydraulics

Other designs and materials also available. | ||||||

Type | Profil | Description | Materials | Temperature in °C | Pressure in bar / MPa | Sliding speed in m/s |

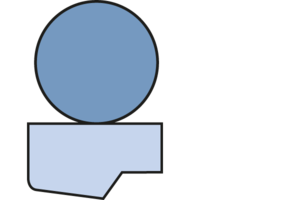

| SRS-D1 |  | Rod seal double acting | PTFE-bronze O-ring NBR O-ring FKM |

-30 to 100 -15 to 200 |

400 / 40 400 / 40 |

15 15 |

| SRS-1 |  | Rod seal single acting | PTFE-bronze O-ring NBR O-ring FKM |

-15 to 200 |

400 / 40 |

15 15 |

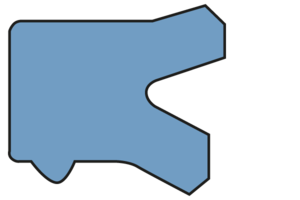

| SRS-D2 |  | Rod seal double acting | PTFE-bronze O-ring NBR O-ring FKM |

-15 to 200 |

160 / 16 |

2 2 |

| SRS-D3 |  | Rod seal double acting | PTFE-bronze O-ring NBR O-ring FKM |

-15 to 200 |

350 / 35 |

15 |

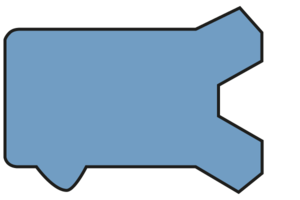

| SRS-2 |  | Rod seal single acting | NBR / Gewebe + NBR +POM FKM / Gewebe + FKM |

-15 to 200 |

400 / 40 |

0,5 0,5 |

| SRS-3 |  | Rod seal single acting | NBR und NBR- Gewebe und POM | -30 to 100 | 400 / 40 | 0,5 |

| SRS-4 |  | Rod seal single acting | NBR TPU | -30 to 100 -40 to 100 | 400 / 40 400 / 40 | 0,5 0,5 |

| SRS-5 |  | Rod seal single acting | TPU | -40 to 100 | 400 / 40 | 0,5 |

| SRS-6 |  | Rod seal single acting | TPU | -40 to 100 | 400 / 40 | 0,5 |

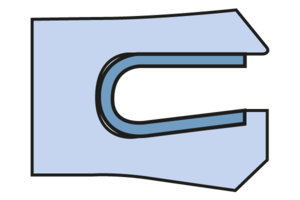

| SRS-7 |  | Rod seal single acting | PTFE Kohle / Graphit V-Feder: 1.4310 | -150 to 250 | 350 / 35 | 15 |

| SRS-8 |  | Rod seal single acting | PU with NBR V-spring:1.4310 | -45 to 110 | 350 / 35 bis 700 / 70 | 0,5 to 1,0 |

| KSRP-1 |  | Rod and Piston packing single acting | NBR und NBR/Gewebe | -30 to 100 | 200 / 20 | 0,5 |

| KSRP-2 |  | Rod and Piston packing single acting | TPU NBR | -40 to 100 -30 to 100 | 300 / 30 160 / 16 | 0,5 0,5 |

| KSRP-3 |  | Rod and Piston packing single acting | TPU | -40 to 100 | 400 / 40 | 0,5 |